When preparing to open a hot pot restaurant, one of the most crucial decisions for restaurant owners is the selection of hot pot tables. As budgets vary for each restaurant, price is often a significant consideration when choosing and purchasing hot pot tables. The prices of different hot pot tables can vary significantly, influenced by several key factors. Here are some factors that may impact the prices of hot pot tables.

Choice of Materials

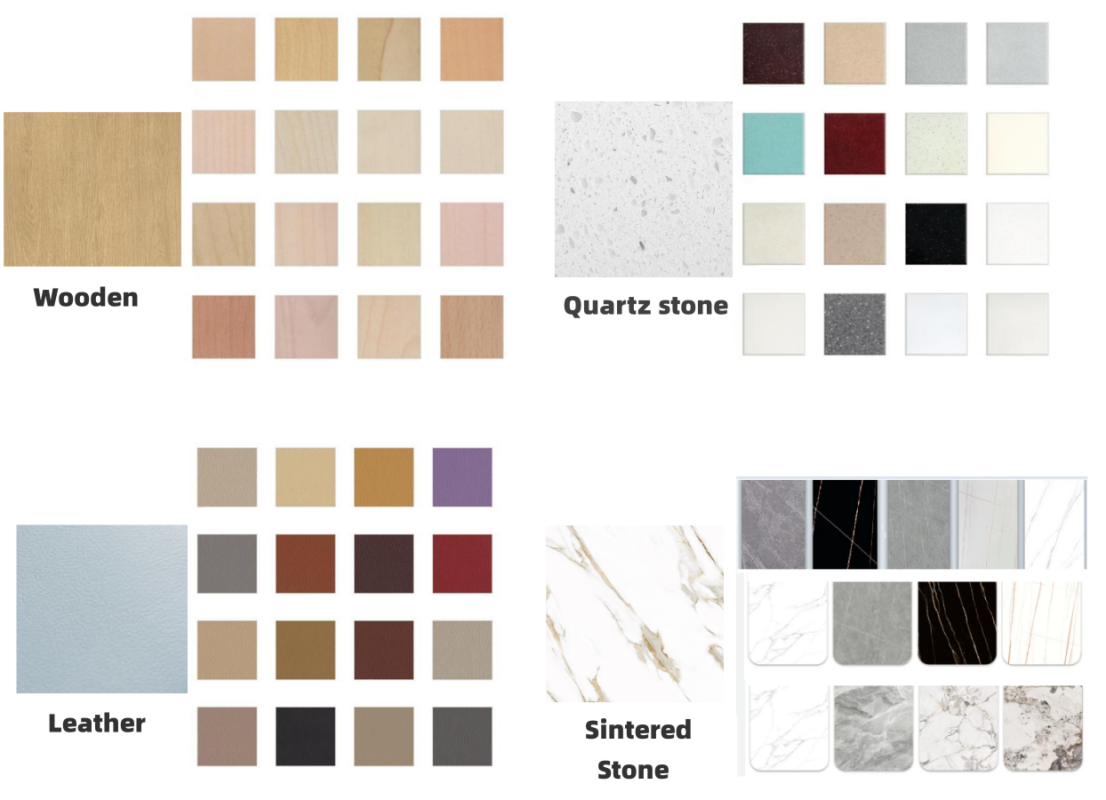

The primary tabletop material of a hot pot table significantly influences its price. Common materials for hot pot tables include marble, sintered stone, quartz stone, firestone, stainless steel, solid wood, and more.

Quartz stone is the most expensive of all tabletop materials. The relatively higher cost of quartz stone tabletops is attributed to the fact that natural quartz minerals are one of the main raw materials for quartz stone, and the extraction and processing costs of these minerals are relatively high. This directly affects the cost of quartz stone tabletops. Additionally, quartz stone tabletops exhibit excellent wear resistance, temperature resistance, and resistance to chemical corrosion, showcasing outstanding performance and durability. This high level of durability and quality is one of the reasons for its higher price. Hot pot tables with quartz stone tabletops can last for ten years or even longer.

The price of solid wood tabletops is second only to quartz stone, as high-quality, finely textured natural wood comes with a relatively higher cost. Solid wood tabletops usually require exquisite craftsmanship and meticulous processing. Wood craftsmen need to spend a significant amount of time selecting, cutting, assembling, and polishing the wood to ensure the texture and quality of the tabletop. This handmade process is labor-intensive, thereby increasing the overall cost. Additionally, high-quality solid wood tabletops tend to become more durable with prolonged use, which is another reason for their higher price.

Stainless steel tabletops have a higher price compared to regular marble tabletops due to their outstanding durability and corrosion resistance. Stainless steel is a high-quality alloy material, composed mainly of iron, chromium, nickel, and other elements, which enhance its corrosion resistance and wear resistance. Therefore, the raw material cost of stainless steel is relatively high, directly impacting the manufacturing cost of stainless steel tabletops. Additionally, stainless steel tabletops often require surface treatments such as polishing to achieve a smooth and shiny appearance. These fine processing techniques also contribute to increased manufacturing costs.

Sintered stone is the material with the most delicate patterns among all types of stone, and using it as the tabletop material for hot pot tables can give the table a very delicate and high-end appearance. Sintered stone can simulate the appearance of natural stone by adjusting color, texture, and shape, providing customers with more design choices to meet different aesthetic preferences. Unlike natural stone, sintered stone has a relatively lower raw material cost, and its price is more cost-effective compared to quartz stone. However, the hardness of the sintered stone tabletop is not as high as that of quartz stone.

The plywood tabletop is the most budget-friendly material among all tabletop materials. Since plywood usually utilizes engineered wood or medium-density fiberboard (MDF), these materials have lower costs compared to natural materials like solid wood or stone. Plywood is relatively easy to process and manufacture; it can be easily cut and shaped, making it suitable for large-scale production, significantly reducing factory production costs. Therefore, plywood is the most economical option compared to other materials, and restaurant owners with tighter budgets may consider hot pot tables with plywood tabletops.

Size and shape

The size and shape of the hot pot table are also crucial factors affecting the price. If customers require customized larger tabletop sizes or need tabletops with special shapes, the consumption of materials will be relatively higher than that for standard sizes and shapes. Consequently, the price of the hot pot table will be higher.

Design and craftsmanship

The level of design and craftsmanship of the hot pot table directly influences its price. Exquisite craftsmanship and unique designs typically increase production costs, resulting in higher prices. Metal edging and solid wood edging can make the hot pot table look more aesthetically pleasing and luxurious. If customers require custom metal or solid wood edging, the price will be higher than that of a standard tabletop.

Additional Features and Accessories

Some customers have specific standards for the exhaust system in their restaurants. When ordering a hot pot table, they may need to include additional features such as smokeless purification. Smokeless purification requires the use of a purifier. In such cases, if a purifier is needed, the overall price of the hot pot table will also increase.

Transportation Costs

The transportation costs vary depending on the region, and consequently, the prices of hot pot tables will also differ. Southeast Asia is relatively close, resulting in lower transportation costs. Customers in Europe and America are at a greater distance, leading to higher transportation costs, and the prices are comparatively higher than in Southeast Asia. Additionally, transportation fees may fluctuate based on international situations, causing changes in transportation costs for different regions and, consequently, fluctuations in the prices of hot pot tables.

In addition, fluctuations in the market prices of tabletop materials can sometimes impact the prices of hot pot tables. In summary, choosing hot pot tables that fit both budget and requirements requires a comprehensive consideration of various factors. Understanding how these factors influence prices will assist restaurant owners in making informed purchasing decisions.

Related tutorials

Teach you how to choose an induction cooker.